100000RPM Full Automatic PCB Cutting Machine with Auto Tool Change

Function

Full Automatic PCB Cutting Machine Introduction:

A full automatic PCB cutting machine is an automated depaneling

machine used in surface mount technology (SMT) lines. It features 2

spindles (cutting tools) and is integrated inline with the

production line for continuous workflow. The machine aligns

perfectly with the needs of high-volume, high-precision, and

automated electronics manufacturing, making it a preferred choice

for modern production environments.

Full Automatic PCB Cutting Machine Feature:

1. The PCB cutting machine has dual Spindles for Simultaneous

Cutting

• Two high-speed spindles operate independently or simultaneously.

• Ideal for parallel processing, significantly reducing cutting

time.

• Increases throughput and supports high-volume production.

2. Fully Automated Operation

• Automatic loading/unloading of PCB panels with conveyor or

robotic arms.

• No manual intervention needed — supports 24/7 operation.

• Seamless integration with SMT lines for inline workflow.

3. Vision-Assisted Alignment System

• Equipped with CCD cameras for precise positioning of fiducial

marks.

• Real-time vision correction ensures high cutting accuracy.

• Compensates for PCB misalignment or shrinkage.

4. High-Precision Cutting

• Uses high-speed spindles (typically up to 60,000–100,000 RPM).

• Minimal stress on PCBs — avoids cracks or damages.

• Supports routing complex shapes with tight tolerances.

5. Dust Collection System

• 4HP vacuum dust collector.

• Keeps the cutting area clean and protects machine components.

• Improves workplace cleanliness and operator health.

6. Smart Software & User Interface

• Touchscreen HMI (Human-Machine Interface) for easy operation.

• CAD/CAM integration for importing routing paths.

• Programmable settings for different panel layouts and cutting

depths.

7. Safety and Monitoring

• Includes door interlocks, emergency stop, and safety light

curtains.

• Real-time monitoring of spindle speed, temperature, and motor

load.

• Alerts and automatic shutdown in case of abnormalities.

8. Compact & Modular Design

• Designed to fit into inline SMT environments.

• Modular construction allows for easy maintenance and upgrades.

9. Multi-PCB and Panel Support

• Supports multi-up panels, different board sizes, and V-cut/tab

routing.

• Adjustable fixtures and vacuum tables for secure board holding.

10. Energy-Efficient Operation

• Designed for low power consumption despite high-speed operation.

• Intelligent standby modes reduce energy usage when idle.

Full Automatic PCB Cutting Machine Specification:

| Model Number | SMTIR500 |

| Machine Size | Approx 2250(L)x1300(W)x1750(H)mm |

| Machine Weight | Approx 800kgs |

| Max PCB Size | 300x450mm (customized), Dual tables |

| PCB Thickness | 0.4-6mm |

| Transmission Height | 900±50mm |

| Transmission Direction | Left -> Right or Right -> Left |

| Transportation Speed | 1500mm/s |

| Feeding Mode | Section type transportation guide rail |

| Rail Width Adjustment | Auto |

| Communication Signal | SMEMA |

| PCB Positioning | Fixtures positioning |

| Picking System | Vacuum, 40-60 nozzles |

| Cutting Spindle | 100000rpm/min |

| Cooling Type | Self cooling |

| Automatic Tool Change | Yes |

| Break Knife Checking | Yes |

| Cutting Accuracy | ±0.05mm |

| Routing Bit | 0.8-3.0 Diameter |

| Repeat Accuracy | ±0.01mm |

| Coordinate Moving Speed | 1000mm/s |

| Unloading Mode | ESD Belt |

| Tool Detection | Yes |

| Procedure Programming | Gerber Drawing Import/Editing Program by Visual |

| Air Supply | 5-8kgs/cm2 |

| Power Supply | AC 380V, 50/60Hz, 3KW |

Full Automatic PCB Cutting Machine Advantages:

| Feature | Feature |

| Dual Spindles | Faster processing, higher throughput |

| Inline Automation | Seamless integration, reduced labor |

| Precision Routing | High-quality edges, component safety |

| High-quality edges, component safety | Adaptable to various board layouts |

| Reduced Stress on PCBs | Better yield, fewer cracks/damages |

| Space-Saving Design | Ideal for compact SMT lines |

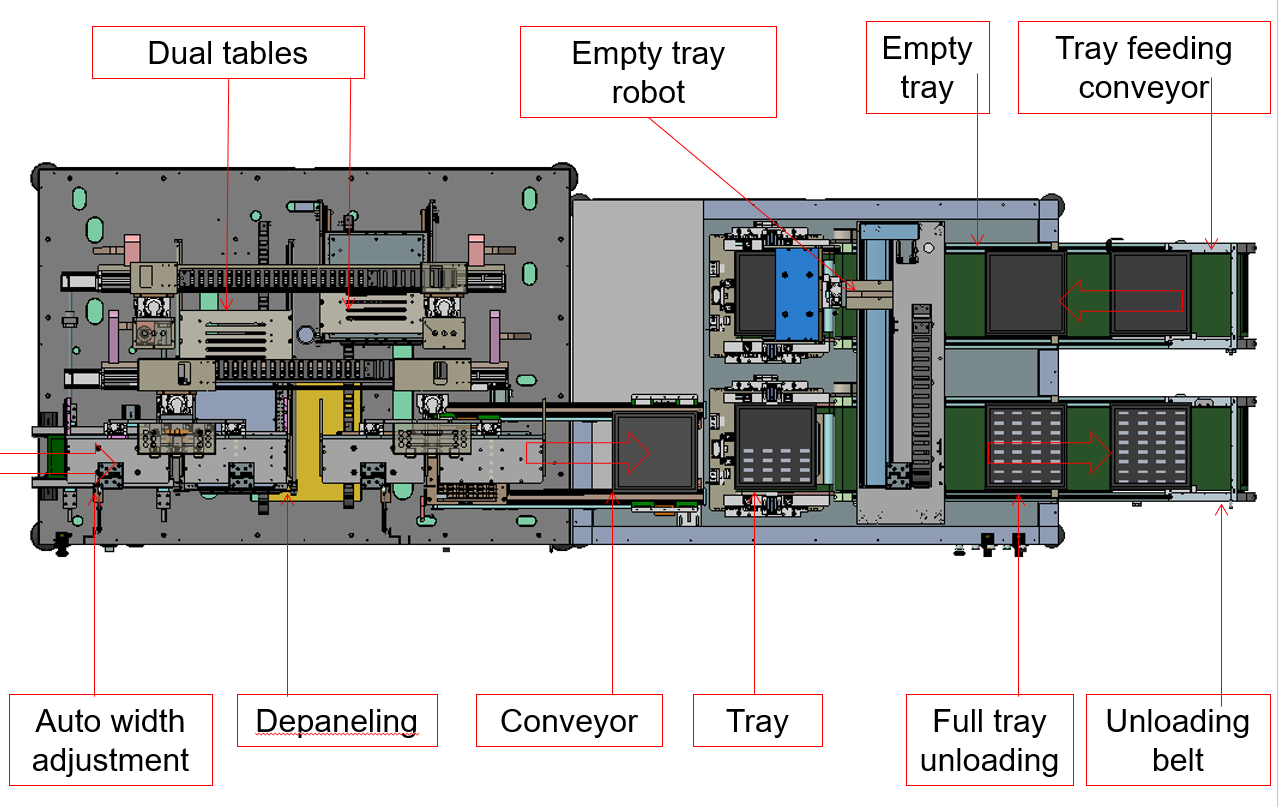

Full Automatic PCB Cutting Machine Connecting Tray Destacker:

This full automatic machine is an advanced depaneling solution

designed for high-speed, high-precision, full automation reduces

reliance on manual operators and minimizes human error.

Two independent worktables allow simultaneous loading and unloading

of PCBs, and it ensures minimal downtime and higher throughput.

Two independent spindles allow for parallel processing of different

PCBA at the same time.

It can also work with a tray destacker machine for a very high

volume production, reduce labor and less rework.