Dual Table Dual Spindle Full Automatic PCB Separator Machine Tray

Destacker

Full Automatic PCB Separator Overview:

Full automatic PCB separator machine has become popular in

electronics manufacturing for several compelling reasons:

High Throughput for Mass Production.

Precision and Quality.

Automation and Integration.

Programmatic Flexibility.

Reduced Human Error.

It is widely used in mass production environments such as

automotive electronics, consumer electronics, LED lighting,

telecommunications, and medical devices.

Full Automatic PCB Separator Feature:

The machine has functions of cutting path full closed loop,

real-time error tracking, feedback, compensation.

It ues Win10 operation system and imported PLC, breaking the

traditional computer-based board PLC control card, higher stability

and stronger anti-interference.

It has twins spindles and twins tables, which can cut 2 boards at

the same time.

This full automatic PCB separator also has tool detection function

and auto change function.

Can connect client's MES system with optional barcode scanner

function.

Full Automatic PCB Separator Specification:

| Model Number | SMTIR500 |

| Machine Size | Approx 2250(L)x1300(W)x1750(H)mm |

| Machine Weight | Approx 800kgs |

| Max PCB Size | 300x450mm (customized), Dual tables |

| PCB Thickness | 0.4-6mm |

| Transmission Height | 900±50mm |

| Transmission Direction | Left -> Right or Right -> Left |

| Transportation Speed | 1500mm/s |

| Feeding Mode | Section type transportation guide rail |

| Rail Width Adjustment | Auto |

| Communication Signal | SMEMA |

| PCB Positioning | Fixtures positioning |

| Picking System | Vacuum, 40-60 nozzles |

| Cutting Spindle | 100000rpm/min |

| Cooling Type | Self cooling |

| Automatic Tool Change | Yes |

| Break Knife Checking | Yes |

| Cutting Accuracy | ±0.05mm |

| Routing Bit | 0.8-3.0 Diameter |

| Repeat Accuracy | ±0.01mm |

| Coordinate Moving Speed | 1000mm/s |

| Unloading Mode | ESD Belt |

| Tool Detection | Yes |

| Procedure Programming | Gerber Drawing Import/Editing Program by Visual |

| Air Supply | 5-8kgs/cm2 |

| Power Supply | AC 380V, 50/60Hz, 3KW |

Full Automatic PCB Separator Comparation with Other Depaneling

Solution:

| Depaneling Method | Pros | Cons |

| Manual Breaking | Low cost | High stress, poor quality |

| V-Score Cutter | Fast for simple boards | Limited to straight lines |

| Punching/Die Cutting | Fast for high volume | Expensive tooling, inflexible |

| Offline Router | Good quality | Manual loading/unloading |

| Inline Router | Best quality, fully automated | Higher initial cost |

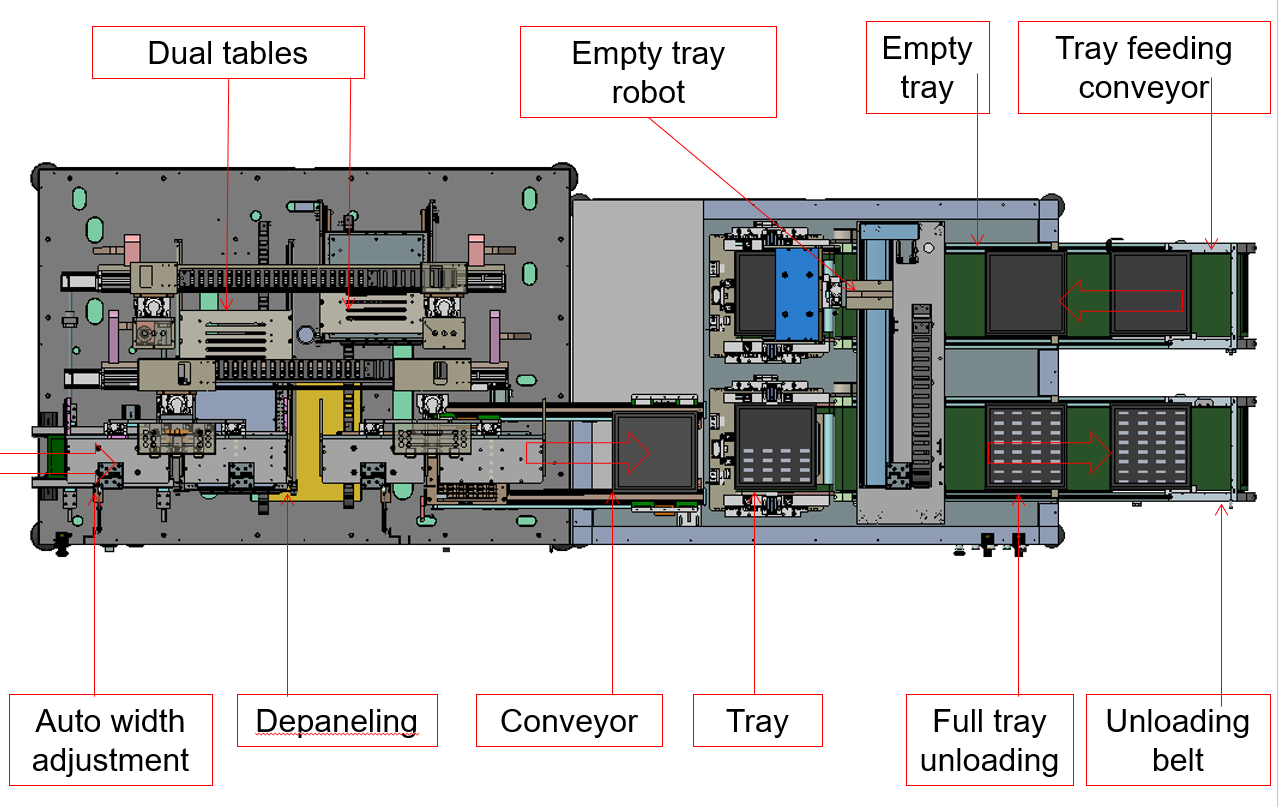

Full Automatic PCB Separator Machine Connecting Tray Destacker:

This full automatic machine is an advanced depaneling solution

designed for high-speed, high-precision, full automation reduces

reliance on manual operators and minimizes human error.

Two independent worktables allow simultaneous loading and unloading

of PCBs, and it ensures minimal downtime and higher throughput.

Two independent spindles allow for parallel processing of different

PCBA at the same time.

It can also work with a tray destacker machine for a very high

volume production, reduce labor and less rework.

Reasons why choose us:

1. Stable: the main components of equipment are imported. The

equipment weight over 700kg. Master the most mature production

technology in the automation industry.

2. Professional: we have many patented technologies in the

automation industry.

3. Innovation: we always committed to developing equipment that is

more labor-saving, highly automated, and has better universality.

4. Fast: response to customer demands within 1 hour, and provide a

solution within 2 hours.