LCD Display Screw Fastening System Automatic Screwdriver Machine

Robotic Screw Fastening System Features:

1. Automatic screw line, feeding, automatic selection of profiled

screws, automatic replenishment of empty materials.

2. No need hand to take the screws by hand, automatic screw

feeding.

3. Efficiency can be 120 pieces per minute.

4. Versatility, electric screwdriver can be hand-held , flexible

operation, suitable for fixed-point operation.

5. Lightweight of the electric screwdriver, accurate and convenient

torque adjustment guarantees the screw fastening quality.

6. Small shape, conveying distance up to 4 meters, the machine can

be placed on the workbench or under the table, space saving.

7. One-hand locking operation, easy to press the screwdriver to

complete the screw fastening.

8. Screw supply fast and reliable, fastening can be done in any

direction.

9. Safe and no noise.

10. LCD screen, counting and alarm function.

Robotic Screw Fastening System Overview:

This equipment increases throughput on a variety of assembly

applications.

This system is completely integrated and include robot, electric

drivers, screw feeder systems.

The controller can store programs.

Robotic Screw Fastening System Process

Compared to other manufacturing methods, automatic screw machining

offers a number of advantages, including:

1. Automation: Automatic screw machines can run with little

operator oversight. They generally only require assistance during

setup and changeover.

2. Efficiency: 2 seconds per screw, increases efficiency of

production.

3. Save money

Robotic Screw Fastening System Specifications:

| Dimension | 585*450*690mm (L*H*W) |

| Power | AC220V 50HZ |

| Frame material | Aluminum alloy |

| Positioning accuracy | X, Y: ± 0.08mm Z: ± 0.01mm |

| Running speed | 500mm/s |

| Working area | 300*280*70mm (X*Y*Z)can be customized |

| Driver | 6-axis precision stepper motor (servo motor to be customized) |

| Control system | PLC + touch screen control system |

| Screw delivery method | Suction type |

| Program storage | 100 groups of programs,100 points each |

| Communication port | USB |

| Air source | 0.4Mpa |

| Alarm items | Floating,Screw wrong target,Leakage lock |

| Bad screws | Alarm |

| Transmission | Precision timing belt (ball screw to be customized) |

| Machine gross weight | About 50kg |

Robotic Screw Fastening System Display:

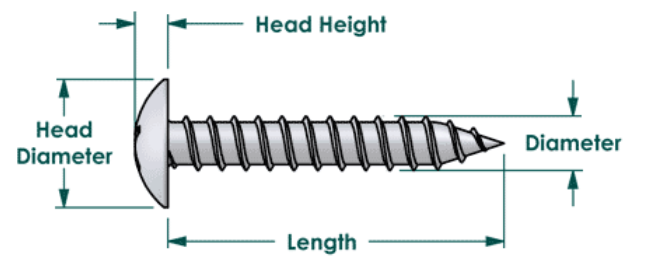

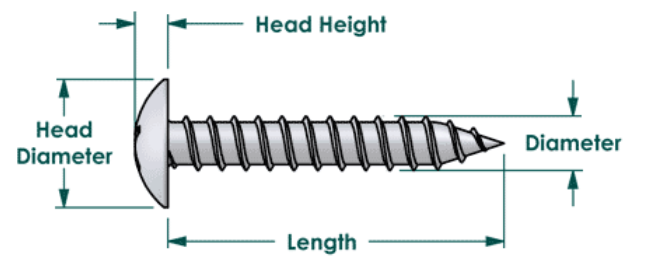

Please advise below screw specification for solution

recommendation.