6KG/Cm2 Air Visual CCD System Top Vacuum Cleaner PCB Depaneling

Router

The PCB Depaneling Router is an advanced machine designed for

precise and efficient PCB depaneling. It incorporates a visual CCD

(Charge-Coupled Device) system for accurate alignment and a top

vacuum cleaning mechanism for debris removal. This machine ensures

high-quality cuts and maintains cleanliness during the depaneling

process, making it suitable for demanding PCB manufacturing

environments.

PCB Depaneling Router Features:

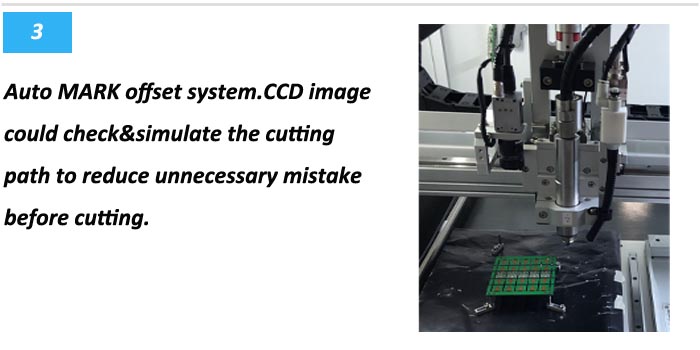

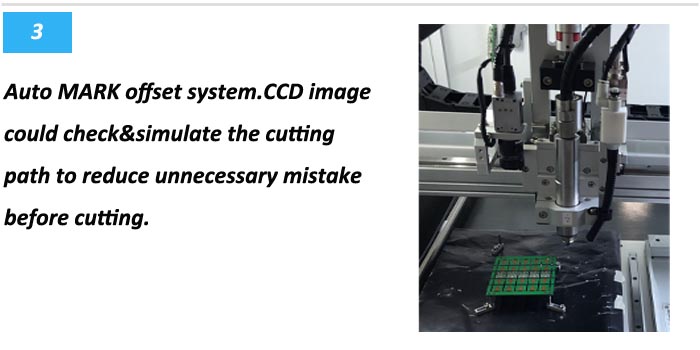

- Visual CCD System: The machine is equipped with a visual CCD system

that captures high-resolution images of the PCB, allowing for

precise alignment of the cutting path. This ensures accurate cuts

and minimizes the risk of damaging sensitive components.

- Top Vacuum Cleaning: The machine utilizes a top vacuum cleaning

mechanism to capture and remove debris generated during the cutting

process. This helps maintain a clean work area, preventing debris

from interfering with the cutting accuracy and ensuring the

cleanliness of the PCB.

- Precision Cutting: The machine incorporates a high-precision

cutting mechanism, such as a router or a milling tool, to achieve

clean and precise cuts. This ensures minimal stress on the PCB and

reduces the chance of damage to the components.

- Adjustable Cutting Parameters: The machine allows for adjustable

cutting parameters, such as cutting speed, depth, and feed rate, to

accommodate different PCB materials and thicknesses. This

flexibility ensures optimal cutting performance and adaptability to

various production requirements.

- User-Friendly Interface: The machine features a user-friendly

interface with intuitive controls and visual indicators, making it

easy for operators to set up and operate the machine efficiently.

- Safety Measures: The machine is equipped with safety features, such

as protective covers and emergency stop buttons, to ensure operator

safety during operation.

- Sturdy Construction: The machine is built with robust materials and

precision engineering to ensure stability, durability, and

long-term reliability in demanding production environments.

PCB Depaneling Router Specifications:

| Overall | |

| Dimensions(W*D*H) | 1250mm*1650mm*1450mm |

| Weight | 750KG |

| Height offset | 60~110mm |

| Manipulator | |

| Motor type | JiaBao series |

| Positioning repeatability | 0.001mm |

| Axis working area(max) | 650mm*560mm*50mm |

| Work station | |

| PCB fixation | standard,specialization |

| PCB loading/unloading | manual |

| PCB size (max) | 320*320mm |

| PCB thick (max) | 5mm |

| Fixturing | |

| Rigidity fixturing | Customized make fixture |

| Fixturing fixation | machinery |

| Spindle Motor | |

| Power | 150W |

| Spindle | 60000rpm/min |

| Protect | self/wind cooling |

| Change cutter | Specialization |

| Routing capability | |

| Cutting speed(max.) | 80mm/s |

| Driving speed(max.) | 2500mm/s |

| Precision of cutting | 0.01mm |

| Vacuum System | |

| Vacuum power | 3.5KW AC 380V |

| Vacuum | plumb |

| Utilities | |

| Power | 2.0KW AC380V |

| Air supply | 4-6KG/cm2 |

| Programming | |

| Program edit | Inline |

| Function edit | Line,arc,circula,U-curve |

| Program storage | HDD |

| Vision system | SONE colour CCD |

| milling cutter offset | AUTO |

| Vacuum setup | AUTO |

| Operation Monitors | |

| Iindicator | Iindicator Machine state |

| tool check | Automatic detection tool life, the use of time testing |

| Motor protect | Have overheating, overload, low voltage protection function |

| motor over loading check | Have Overload, the line is normal, low voltage protection function |

| Tool usable time | Automatic detection tool life, |

| Data statistic | Separate board model, separating count, diverse counting methods |

| Error record | Software automatically records all alarms memory of machines |

| III. Accuracy | |

| Axis precision | 0.001mm |

| Cutting precision | 0.1mm |

| IV. Safety | |

| Working area protect | With four sealed protection |

| Door sensor | Front and rear safety door micro-switch sensor (optional) |

| Exigency stop button | |

PCB Depaneling Router Details:

PCB Depaneling Router Applications:

The Visual CCD System Top Vacuum Cleaning PCB Depaneling Router is

suitable for various applications in the PCB manufacturing

industry, including:

- High-Density PCBs: It is ideal for depaneling high-density PCBs

with intricate designs and tightly packed components, ensuring

precise cutting and minimal risk of damage.

- SMD Components: The machine can handle PCBs with surface-mounted

devices (SMDs) and delicate components, providing accurate cuts

while safeguarding the integrity of the components.

- Prototype Development: It is well-suited for prototype development,

allowing for efficient and accurate depaneling of PCBs during the

prototyping stage.

- Small to Medium-Scale Production: The machine is suitable for small

to medium-scale PCB production, offering efficient and reliable

depaneling capabilities while maintaining cleanliness and quality.

- The Visual CCD System Top Vacuum Cleaning PCB Depaneling Router

combines precise cutting, visual alignment, debris removal, and

user-friendly operation, making it an advanced solution for

high-quality PCB depaneling in various manufacturing applications.

PCB Depaneling Router Machine Packaging:

PCB Depaneling Router FAQ:

1.A: What is life time of routing bit?

Q:150-300 meters.

2.A: Can this model cut Aluminum PCB boards?

Q: Yes, it can.

3.A: What about PCB positioning?

Q: Use customized jig for positioning.

4.A:What is the spindle for the inline PCB router?

Q:Germany SycoTec 4025.

5.A:How to package it?

Q:Router and cleaner is packaged into separated wooden case after

vacuum.

6.A:Is on-site installation and training available.

Q:Yes, it is available.

7.A:What is your terms of delivery?

Q:We accept ex-work, FOB, CIF, DDU, DDP, etc.

PCB Depaneling Router Machine Other Models: