Full Automatic Inline PCB Depaneling Router Machine For Automotive

Electronics

Inline PCB Depaneling Router Features:

1. Full automatic for high volume production.

2. PC and CCD vision system for precise cutting.

3. Programming with compensation and dust collection.

4. Bottom cutting and vacuum cleaner system to make PCB surface and

workshop clean.

5. Flexible for different type of products, customized made model

is available.

Inline PCB Depaneling Router Specification:

| Model Number | SMTIR811 |

| Machine Size | 1500(L)x850(W)x1600(H)mm |

| Machine Weight | Approx 800kgs |

| Max PCB Size | 260x340mm (standard) |

| PCB Thickness | 0.4-6mm |

| Transmission Height | 900±50mm |

| Transmission Direction | Left -> Right |

| Transportation Speed | 1500mm/s |

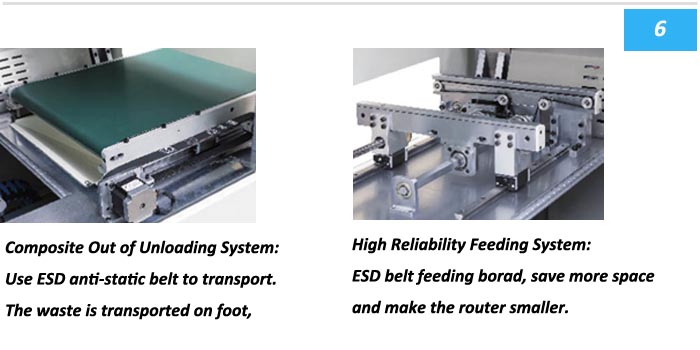

| Feeding Mode | Section type transportation guide rail |

| Rail Width Adjustment | Manual |

| Communication Signal | SMEMA |

| PCB Positioning | Fixtures positioning |

| Picking System | Vacuum |

| Cutting Spindle | SycoTec 60000rpm/min(standard) |

| Cooling Type | Self cooling |

| Automatic Tool Change | Optional |

| Break Knife Checking | Yes |

| Cutting Accuracy | ±0.01mm |

| Routing Bit | 0.8-3.0 Dia, right rotation |

| Repeat Accuracy | ±0.02mm |

| Coordinate Moving Speed | 1000mm/s |

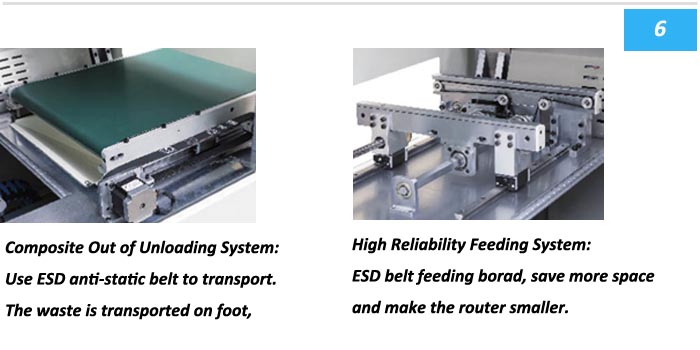

| Unloading Mode | ESD Belt |

| Waste Collection Way | Waste Cupboard Collection |

| Procedure Programming | Gerber Drawing Import/Editing Program by Visual |

| Air Supply | 5-8kgs/cm2 |

| Power Supply | AC380V, 50/60Hz, 3KW |

Inline PCB Depaneling Router Details:

Inline PCB Router Advantages:

1. Inline Operation: The machine is designed for integration into

the production line, allowing for continuous and automated PCB

depaneling. This ensures a smooth workflow and efficient production

processes in automotive electronics manufacturing.

2. Bottom Cutting Capability: The machine is equipped with a

specialized bottom cutting router that accurately cuts and

separates PCBs from the bottom side. This enables precise removal

of the unwanted sections of the PCB, such as breakaway tabs or

panelized edges.

3. Fully Automatic Operation: The machine offers fully automatic

operation, minimizing the need for manual intervention. It can

handle multiple PCBs simultaneously, enhancing production

efficiency and throughput.

4. Precision and Accuracy: With its advanced cutting technology,

the machine ensures high precision and accuracy in bottom cutting.

This results in clean edges, minimal stress on the PCB, and

maintains the integrity of the circuitry and components.

5. Customizable Cutting Parameters: The machine allows for

customization of cutting parameters such as cutting depth, speed,

and tool positioning. This flexibility enables operators to adapt

the machine to specific PCB designs and achieve optimal cutting

results.

6. Conveyor System: The machine is typically equipped with a

conveyor system that transports PCBs through the cutting process.

This ensures smooth and consistent movement of PCBs, reducing the

risk of damage and maintaining production efficiency.

7. Vision System: Some machines may incorporate a vision system for

precise alignment and positioning of PCBs during the cutting

process. This ensures accurate cutting along the predefined cutting

path, improving overall quality and yield.

8. Safety Features: Safety features are integrated into the

machine's design to ensure operator safety. These may include

protective enclosures, emergency stop buttons, and safety

interlocks.

Inline PCB Depaneling Router FAQ:

1.A: What is life time of routing bit?

Q:150-300 meters.

2.A: Can this model cut Aluminum PCB boards?

Q: Yes, it can.

3.A: What about PCB positioning?

Q: Use customized jig for positioning.

4.A:What is the spindle for the inline PCB router?

Q:Germany SycoTec 4025.

5.A:How to package it?

Q:Router and cleaner is packaged into separated wooden case after

vacuum.

6.A:Is on-site installation and training available.

Q:Yes, it is available.

7.A:What is your terms of delivery?

Q:We accept ex-work, FOB, CIF, DDU, DDP, etc.

Our Service:

1. Lifetime technical support and 2 years warranty.

2. Free replacement or refund would be done in case of any quality

problem.

3. Fast response/feedback within 12 hours

4. Engineers are available to be sent to do oversea installation

and training.

5. Solid packaging to prevent damage from transportation.