Air Cylinder Pneumatic Punching Machine 10 Seconds Cycle Punching

Time

Pneumatic Punching Machine Overview:

This machine is a semi-automatic PCB separator. Our factory

complies with the corresponding national production standards. The

warranty period is 1 year from the date of purchase (equipment

damage caused by abnormal use is not included in the warranty)

Punch Press Machine Features:

1. Designed specifically for FPC, hard PCB, CEM, MCPCB boards,

avoid tin crack, cracked, curling, burrs and other phenomena

2. Arbitrary regulation punching speed, punching and stamping time

pressure according to different products and mold.

3. It is easy to replace molds, and the touch screen with a button

for mold-specific passwords, to ensure safe operation.

4. Longitudinal movement of the lower mold for easy placing and

picking PCBs and ensure personal safety.

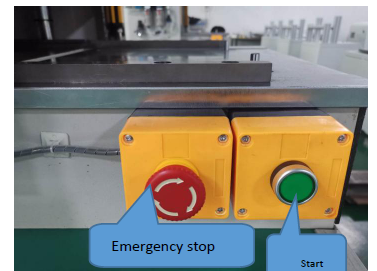

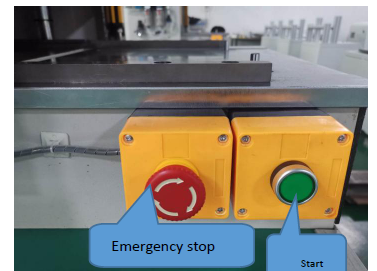

5. Using both hands push button synchronization (within 1 second)

to control, eliminate human safety hazards.

6. Use of clean air, no oil, low power, easy energy saving,

maintenance, fast and stable output.

7. Selectable manual or automatic operation mode, the computer

program in conjunction with the count, the day yield and total

recorded simultaneously, facilitate the statistics, Accurate count

and high efficiency.

8. Use pneumatic technology, a compressor can work for more than

one punch, normal use and maintenance costs were lower than other

types of punch.

Punch Press Machine Specification:

| Working area | 460*320mm |

| Working pressure | 0.45-0.7Mpa |

| Cutting precision | ±0.05mm |

| Cycle time | 7-15 seconds |

| Output | 8T |

| PCB/FPC thickness | 0.08-3.5MM |

| PCB/FPC material | FPC, FR1, FR4, CEM-1, CEM-3, MCPCB |

| Cutting mode | Punching |

| Punch fixture | Die tooling(mold) |

| Working Property | LCD display, Automatically records the number of processed products, automatic punching |

| Transmission port | International standard |

| Operation Language | English |

| Stroke | 50MM |

| Mold height | 170MM |

| Power | 380/220V |

| Fuse | 3A |

| Machine dimension | 820x740x1750mm |

| Machine weight | 680kgs |

Punch Press Machine Punching Mold Installation Steps:

1. Remove the security door

2. Place the two pin holes on the bottom plate of the lower mold on

the two hooks.

3. Feed the upper mold into the drawer(see below picture), and the

mold edge and the upper plate are overlapped.

4. The machine switches to manual mode. Press the “front and back”

button to feed the lower mold into the machine.

5. Disconnect the air source, the upper and lower cylinders will

slowly fall, and the guide post of the upper mold will extend into

the lower mold, and the two will slowly close together.

6. After the upper and lower molds are closed, manually tighten the

thumb screws as shown in the figure. Make sure the upper mold

cannot move. After tightening, the air source is connected, the

cylinder rises, the upper mold is separated, and the air source is

disconnected again to check whether the upper mold and the lower

mold can be closed. Repeat the operation once or twice to ensure

that the upper and lower dies are smoothly closed before proceeding

to the next step.

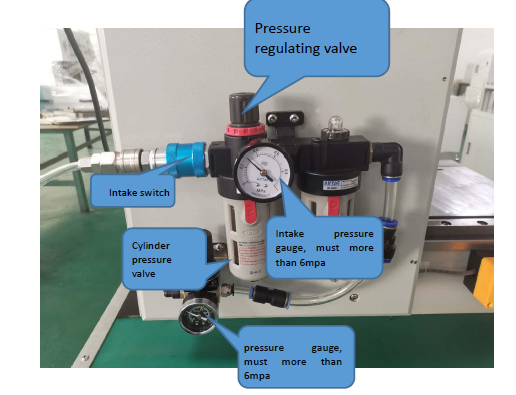

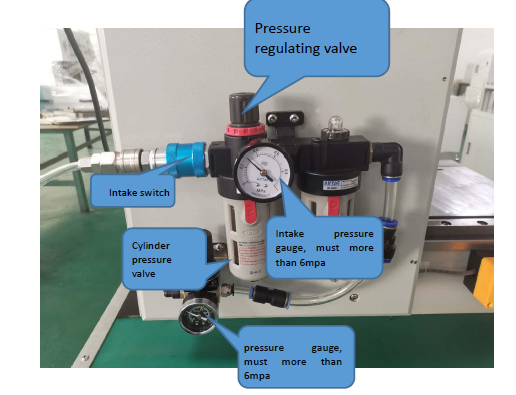

Punch Press Machine Details:

Punch Press Machine Maintenance:

1. Remove waste boards in time.

2. Add grease to the two guide rods every two months, and apply

lubricating oil to

the connecting rod shaft.

3. Remove water from the pressure reducing valve regularly.

4. If the organic parts are damaged, they should be repaired

immediately.